Image 1 of 20

Image 1 of 20

Image 2 of 20

Image 2 of 20

Image 3 of 20

Image 3 of 20

Image 4 of 20

Image 4 of 20

Image 5 of 20

Image 5 of 20

Image 6 of 20

Image 6 of 20

Image 7 of 20

Image 7 of 20

Image 8 of 20

Image 8 of 20

Image 9 of 20

Image 9 of 20

Image 10 of 20

Image 10 of 20

Image 11 of 20

Image 11 of 20

Image 12 of 20

Image 12 of 20

Image 13 of 20

Image 13 of 20

Image 14 of 20

Image 14 of 20

Image 15 of 20

Image 15 of 20

Image 16 of 20

Image 16 of 20

Image 17 of 20

Image 17 of 20

Image 18 of 20

Image 18 of 20

Image 19 of 20

Image 19 of 20

Image 20 of 20

Image 20 of 20

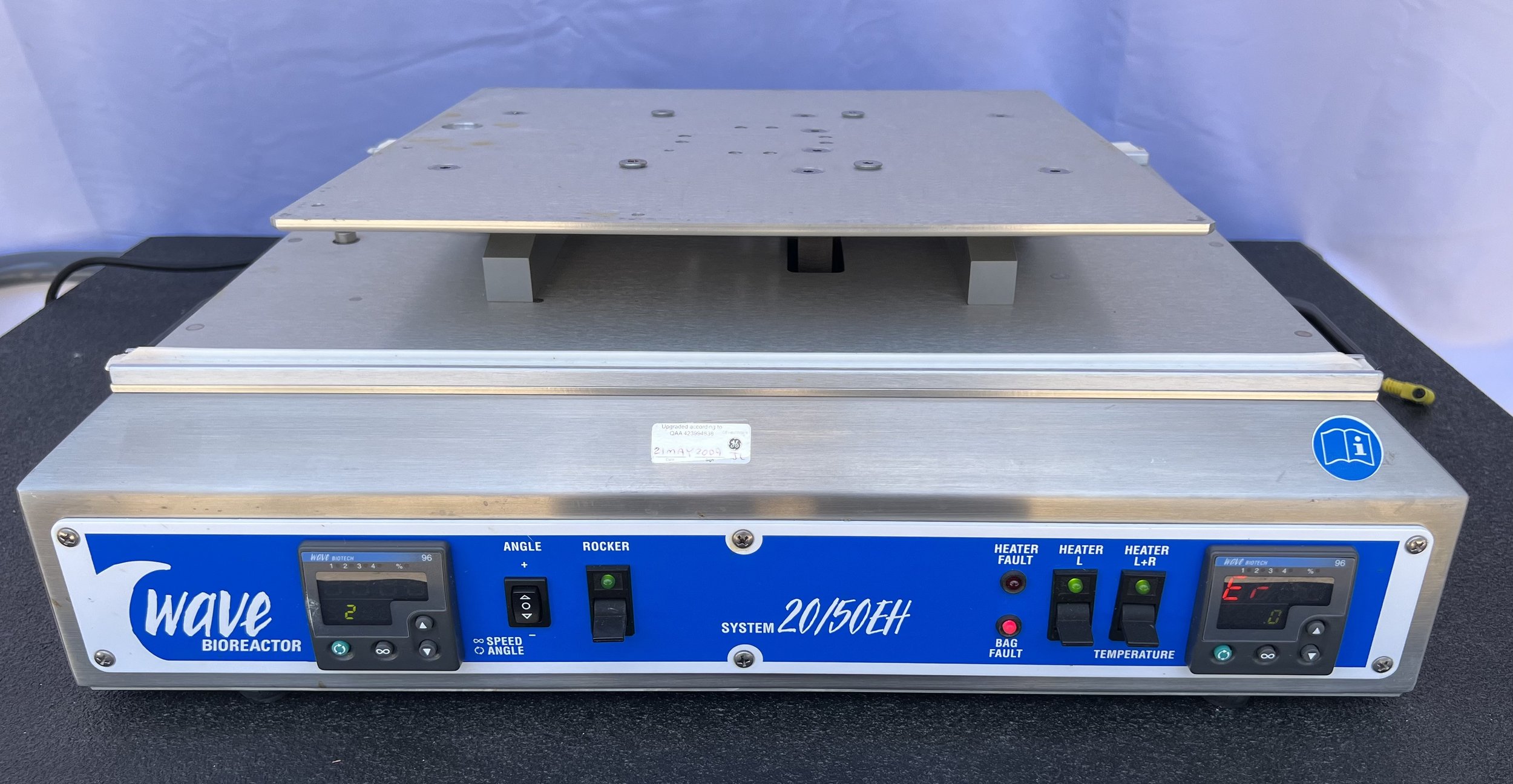

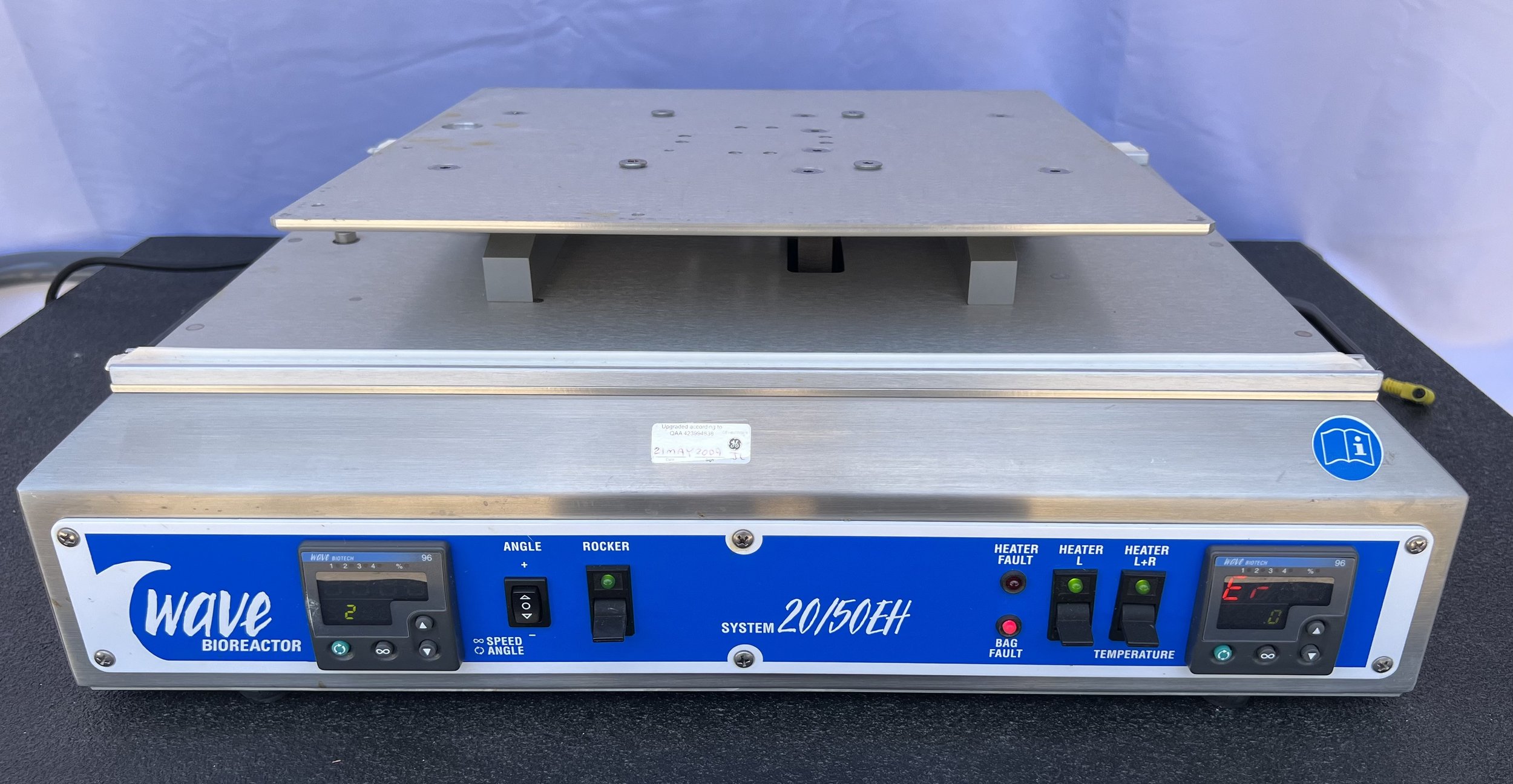

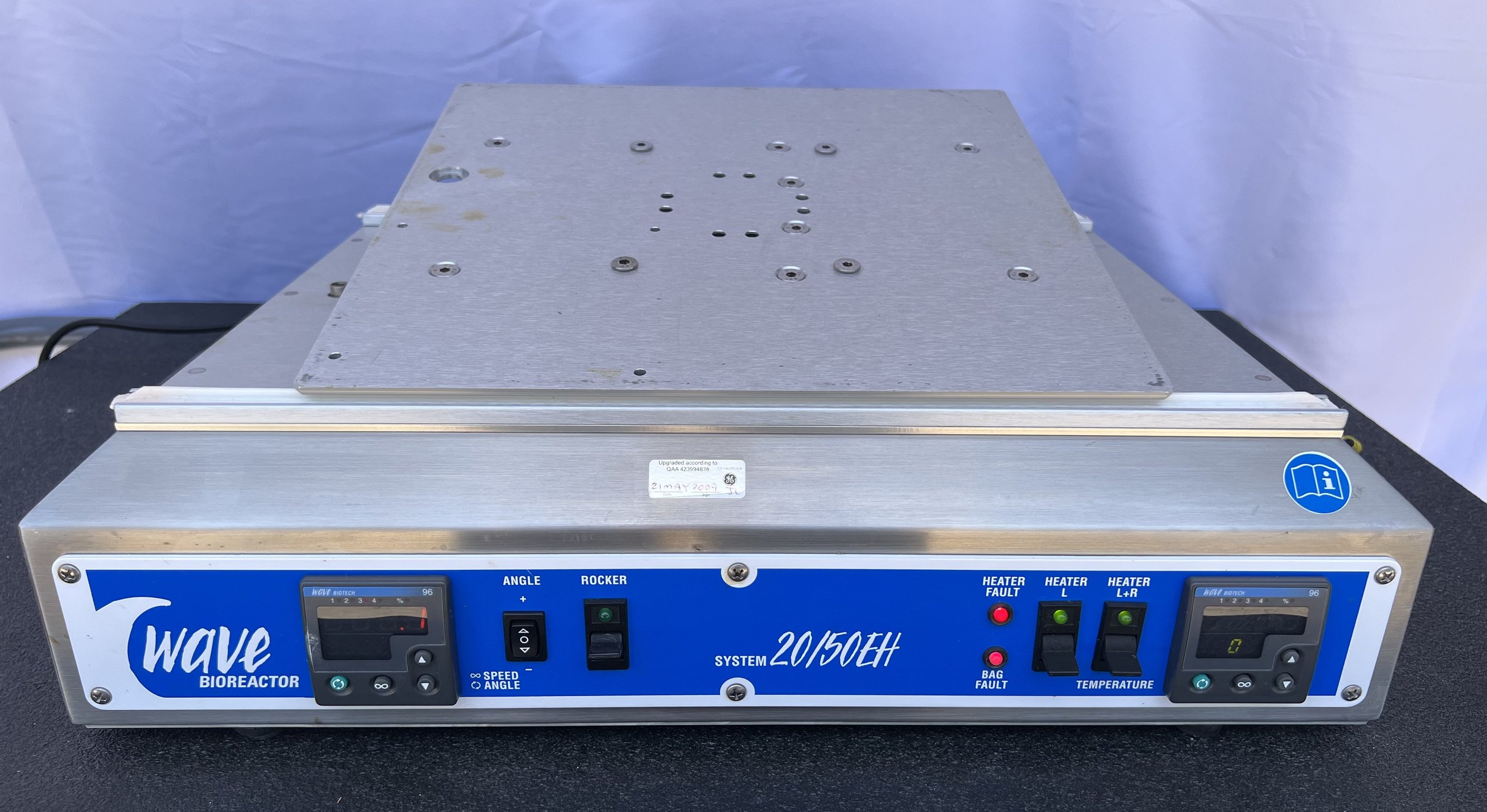

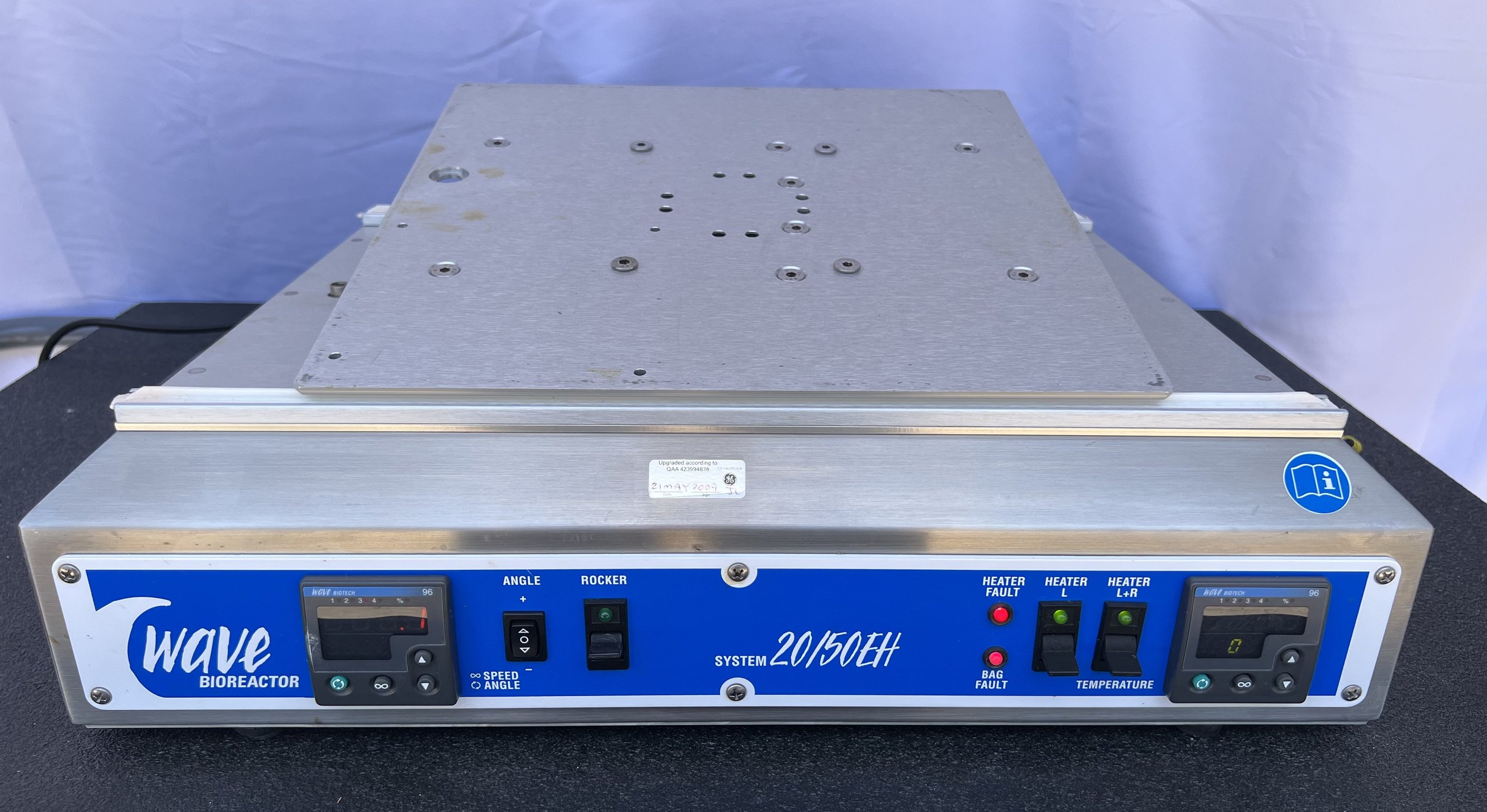

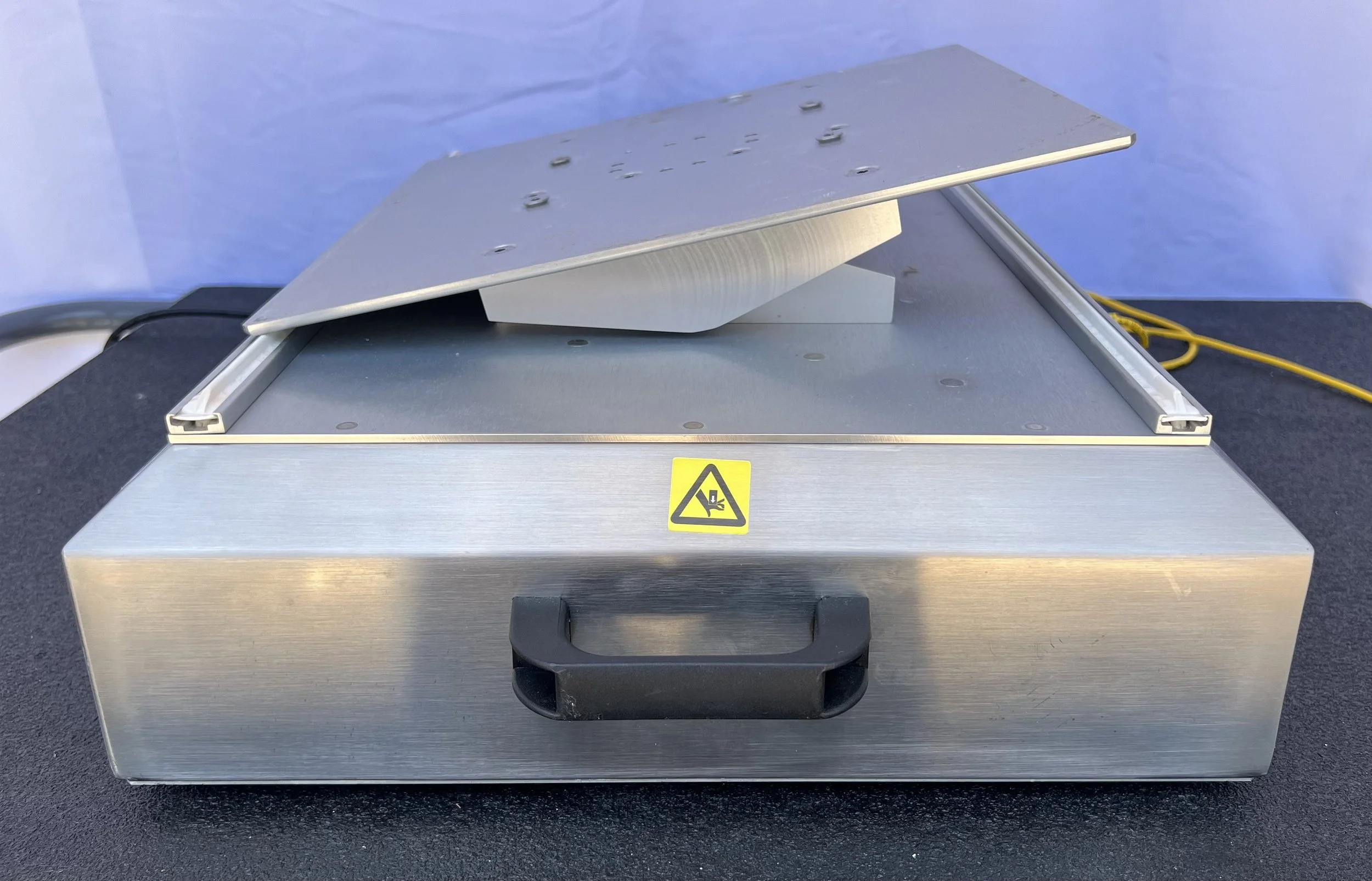

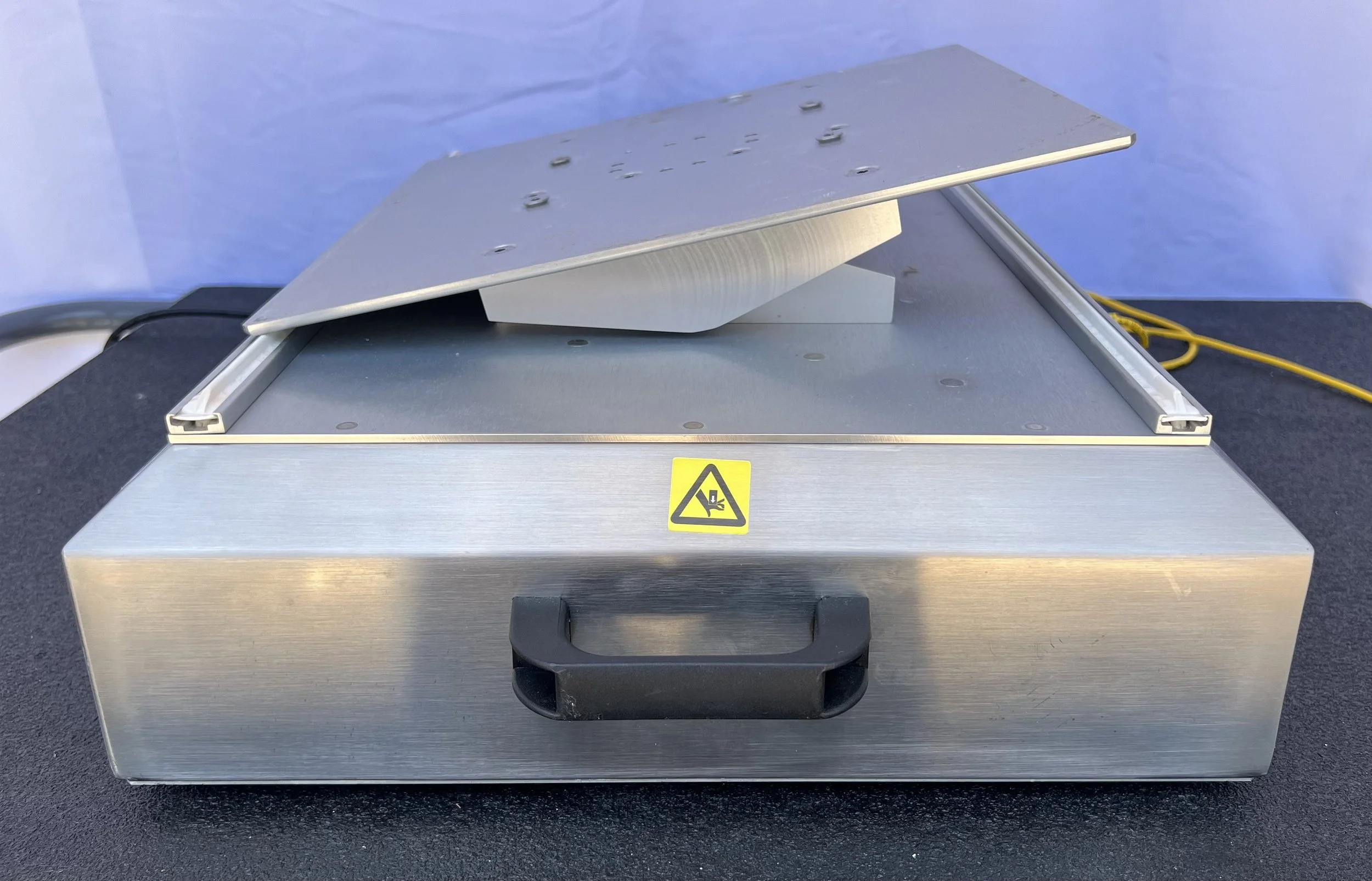

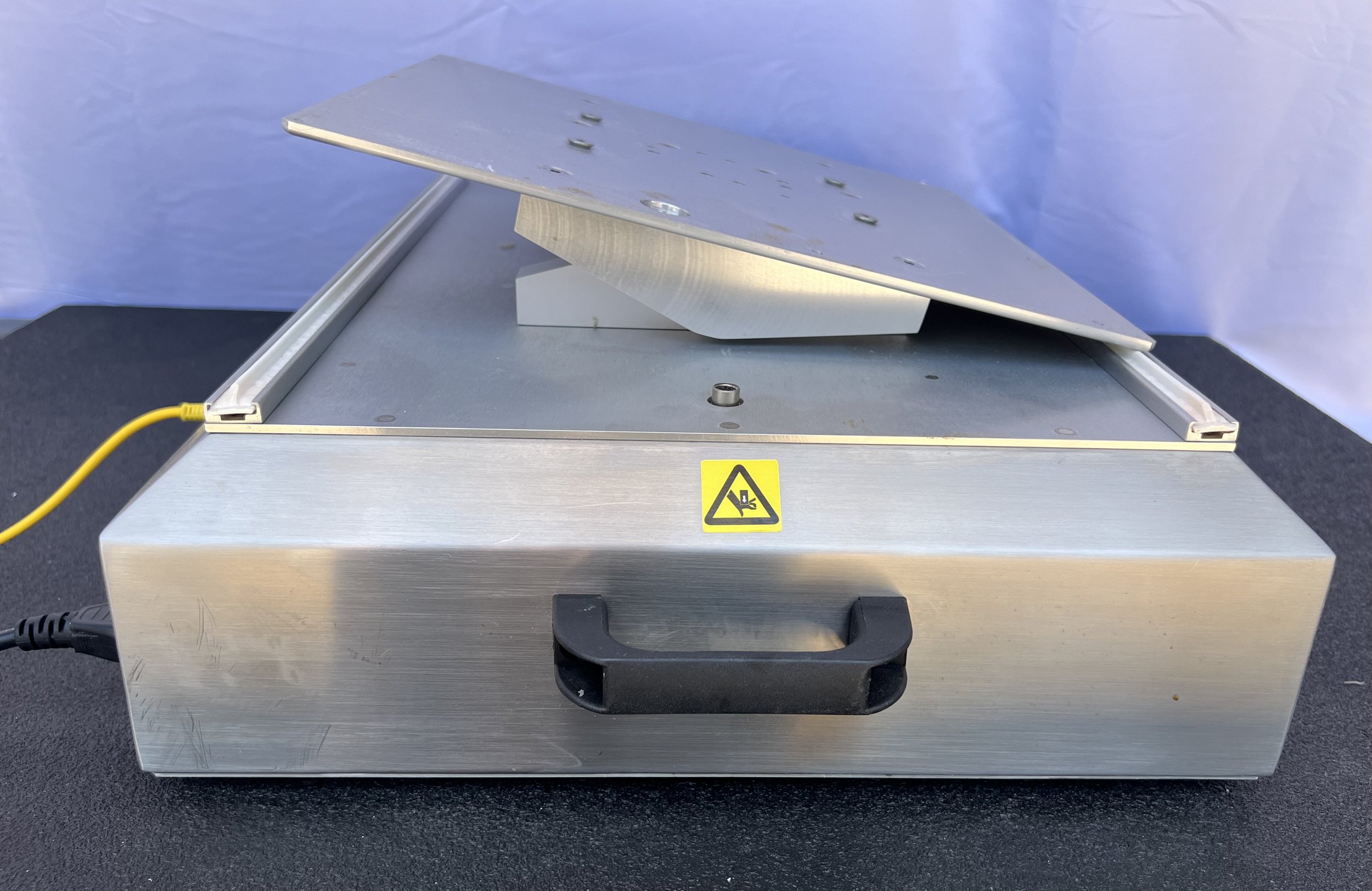

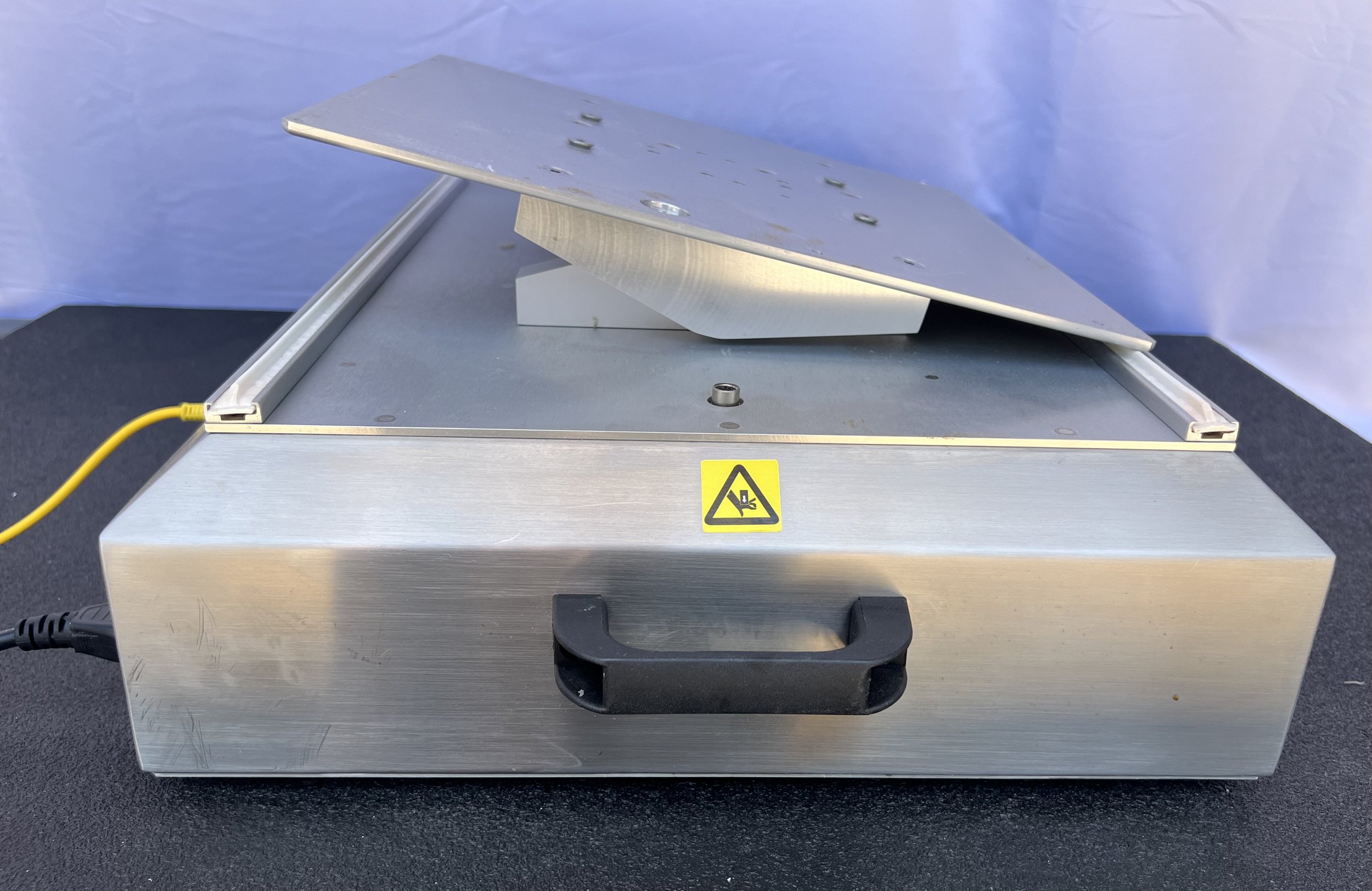

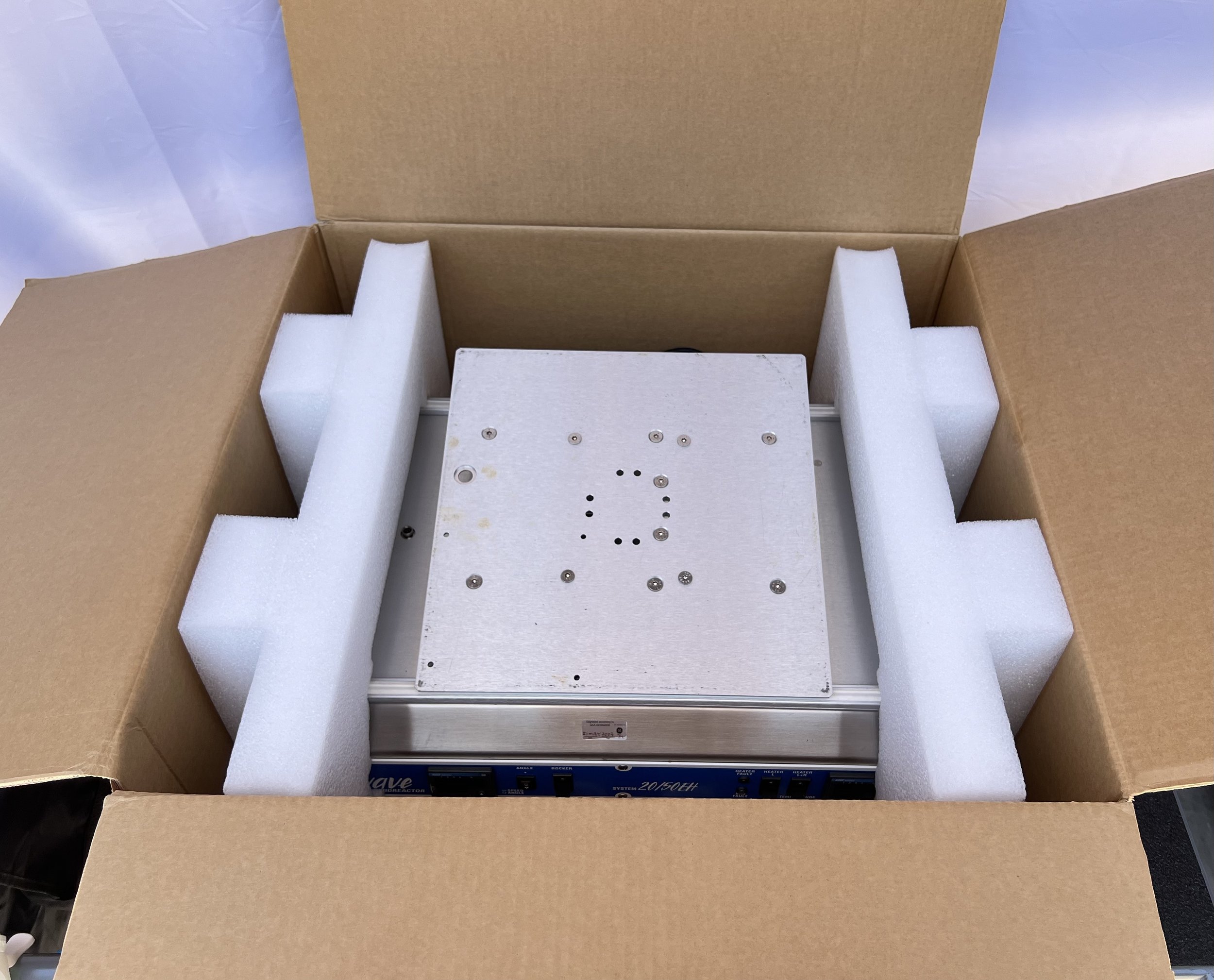

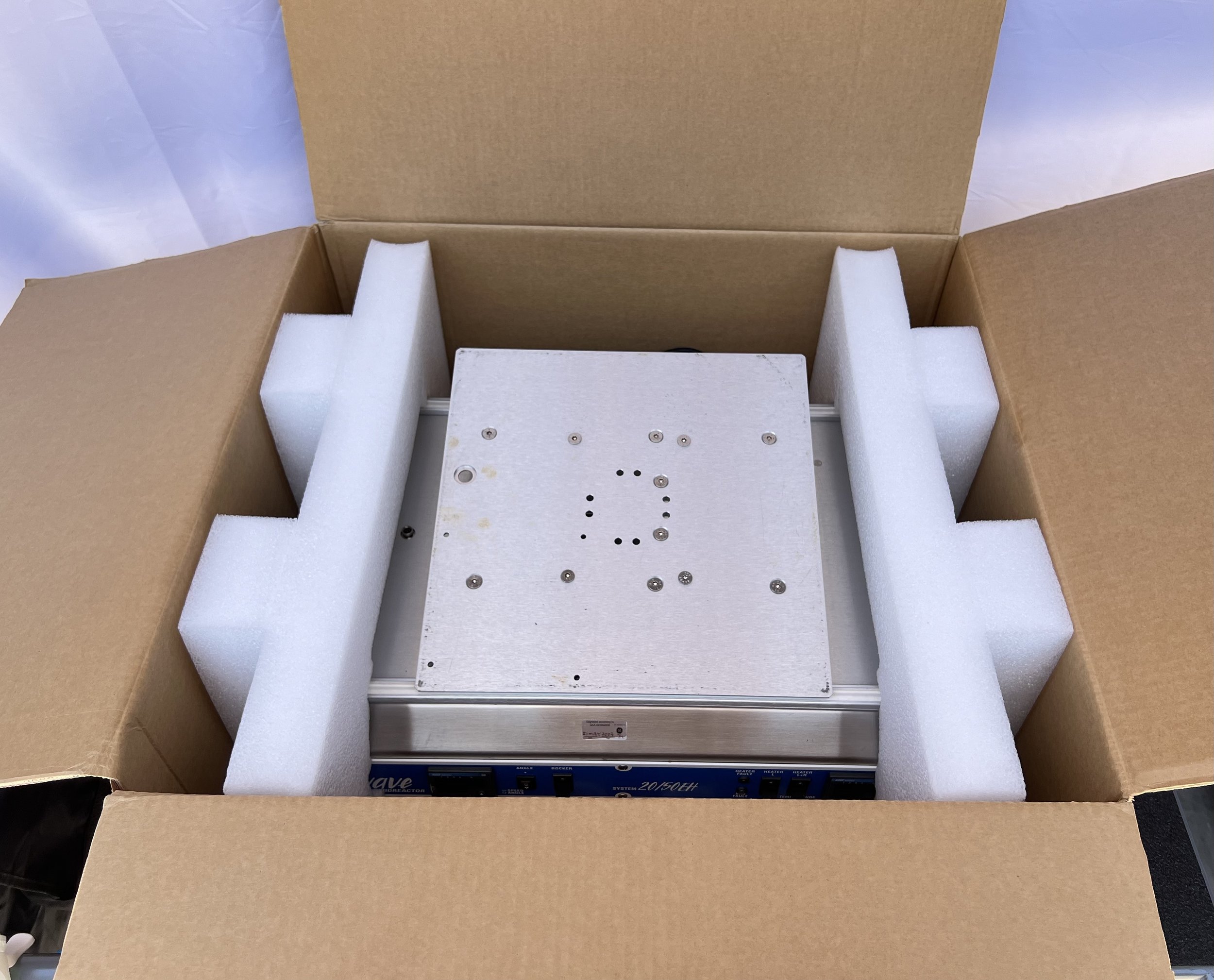

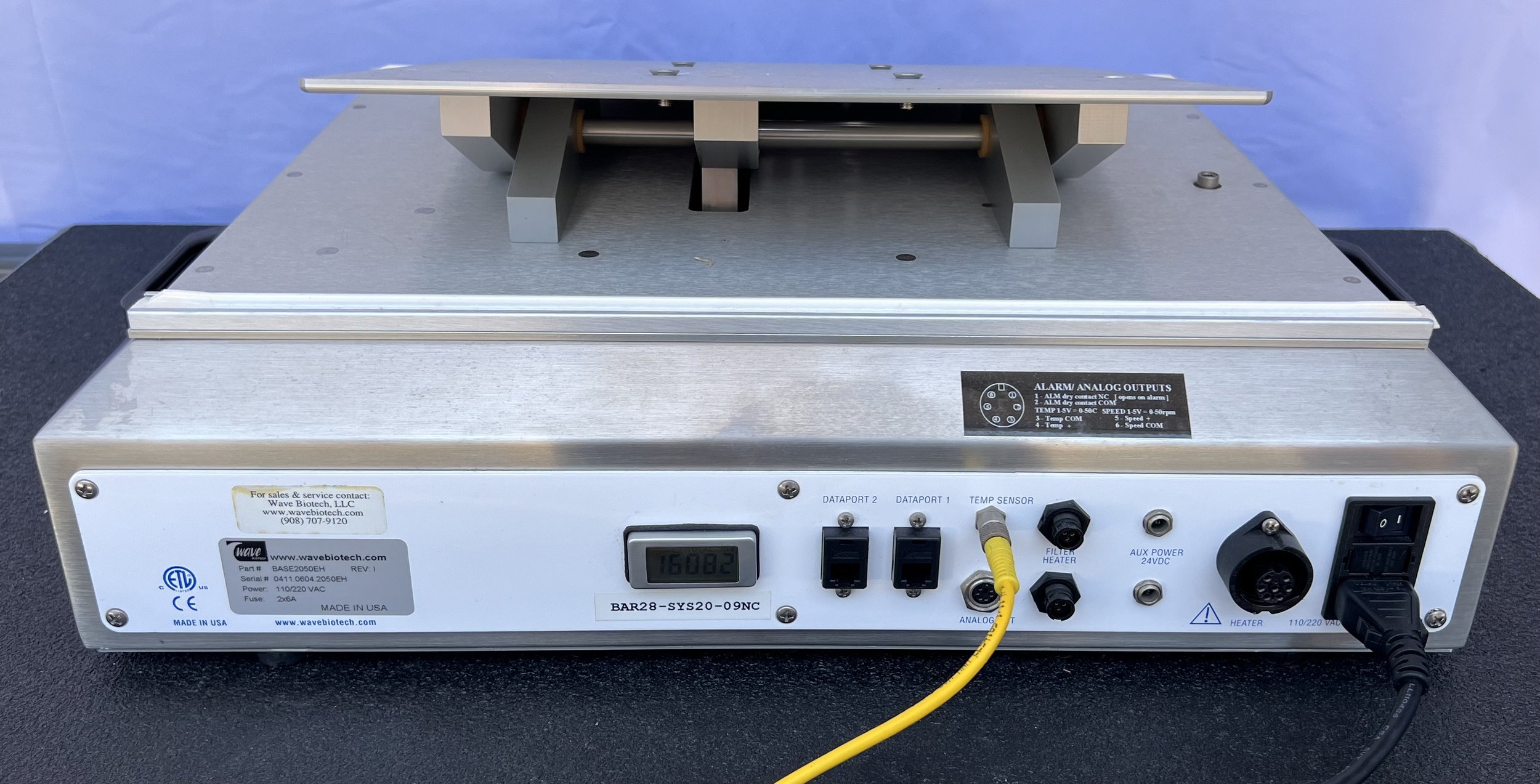

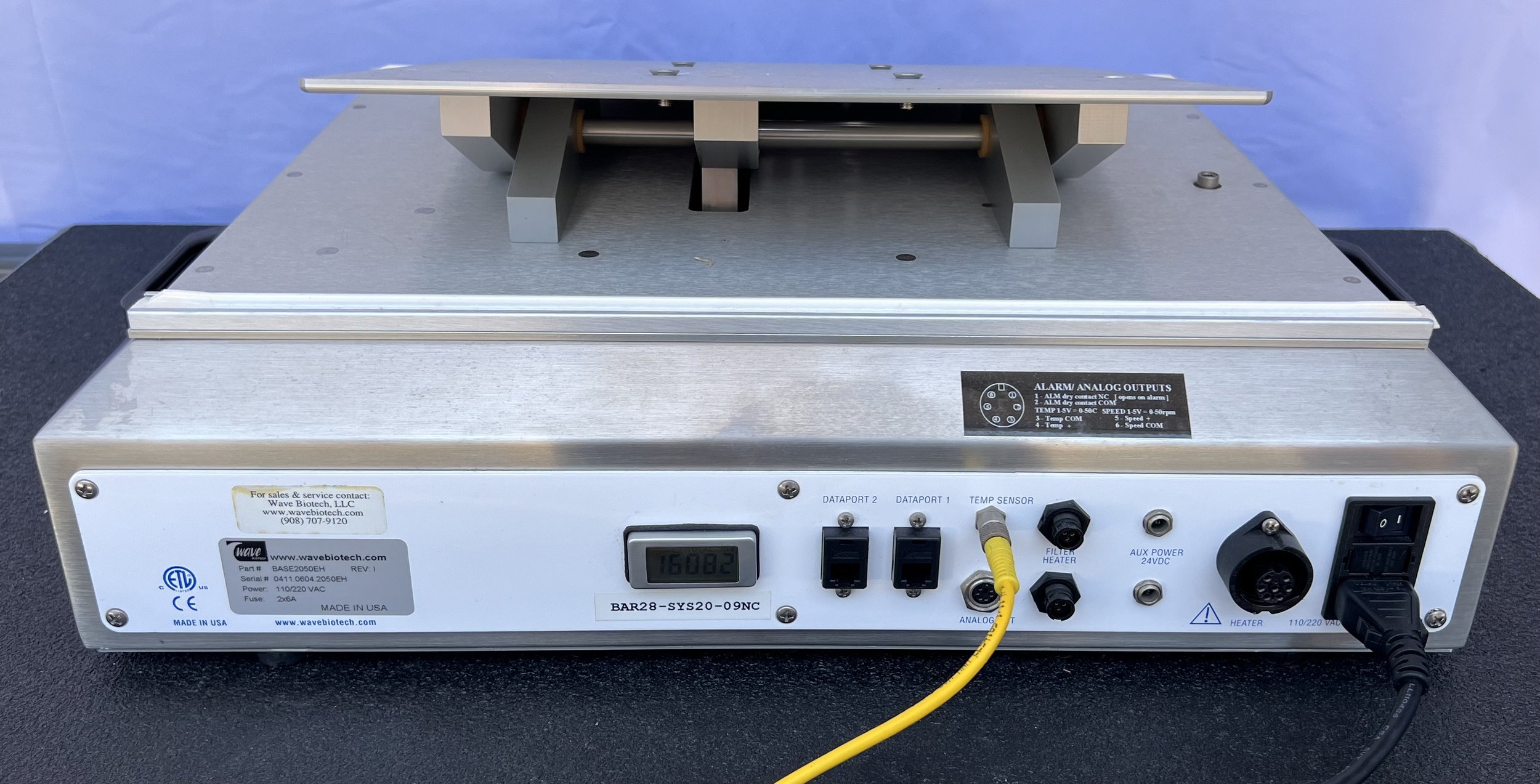

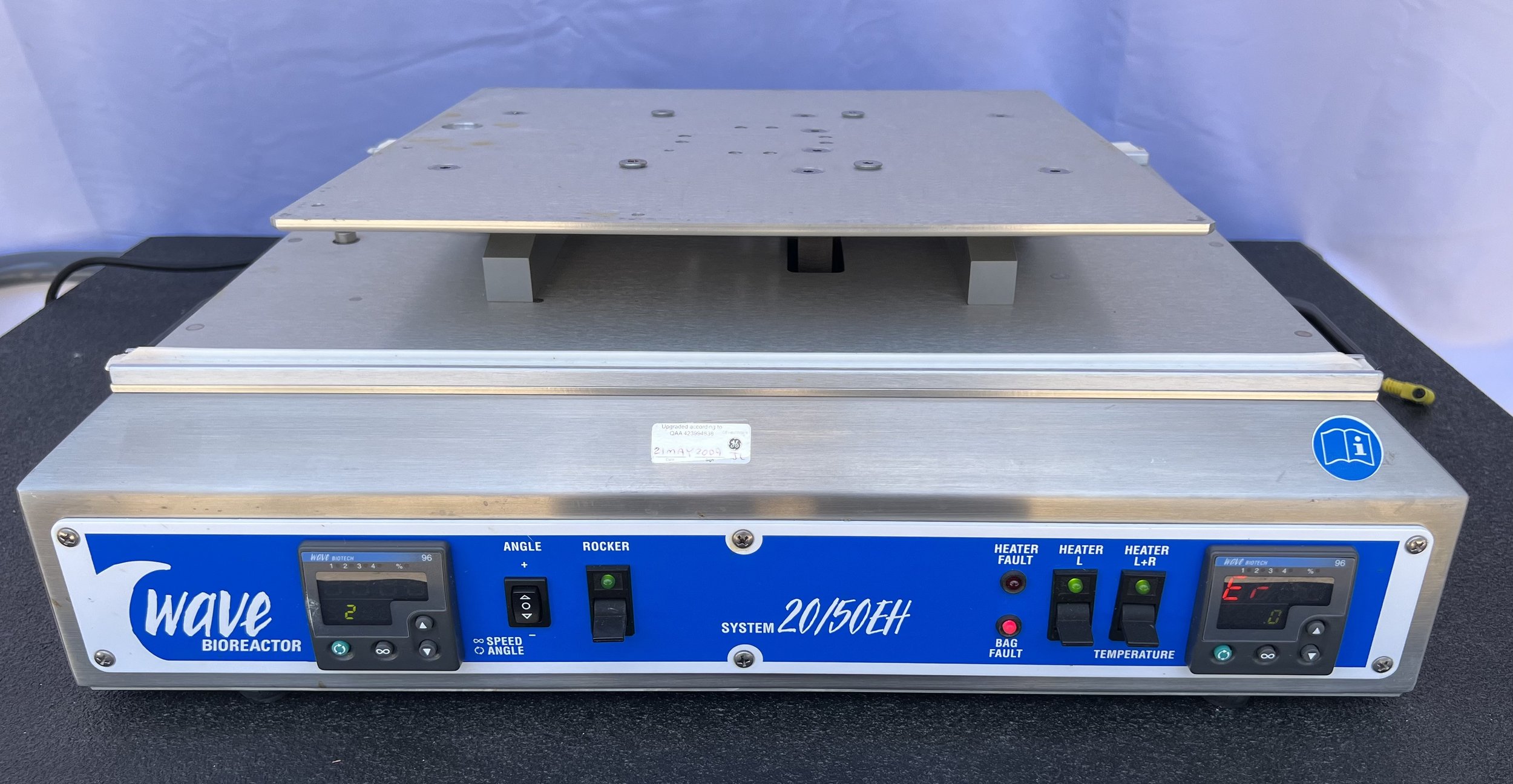

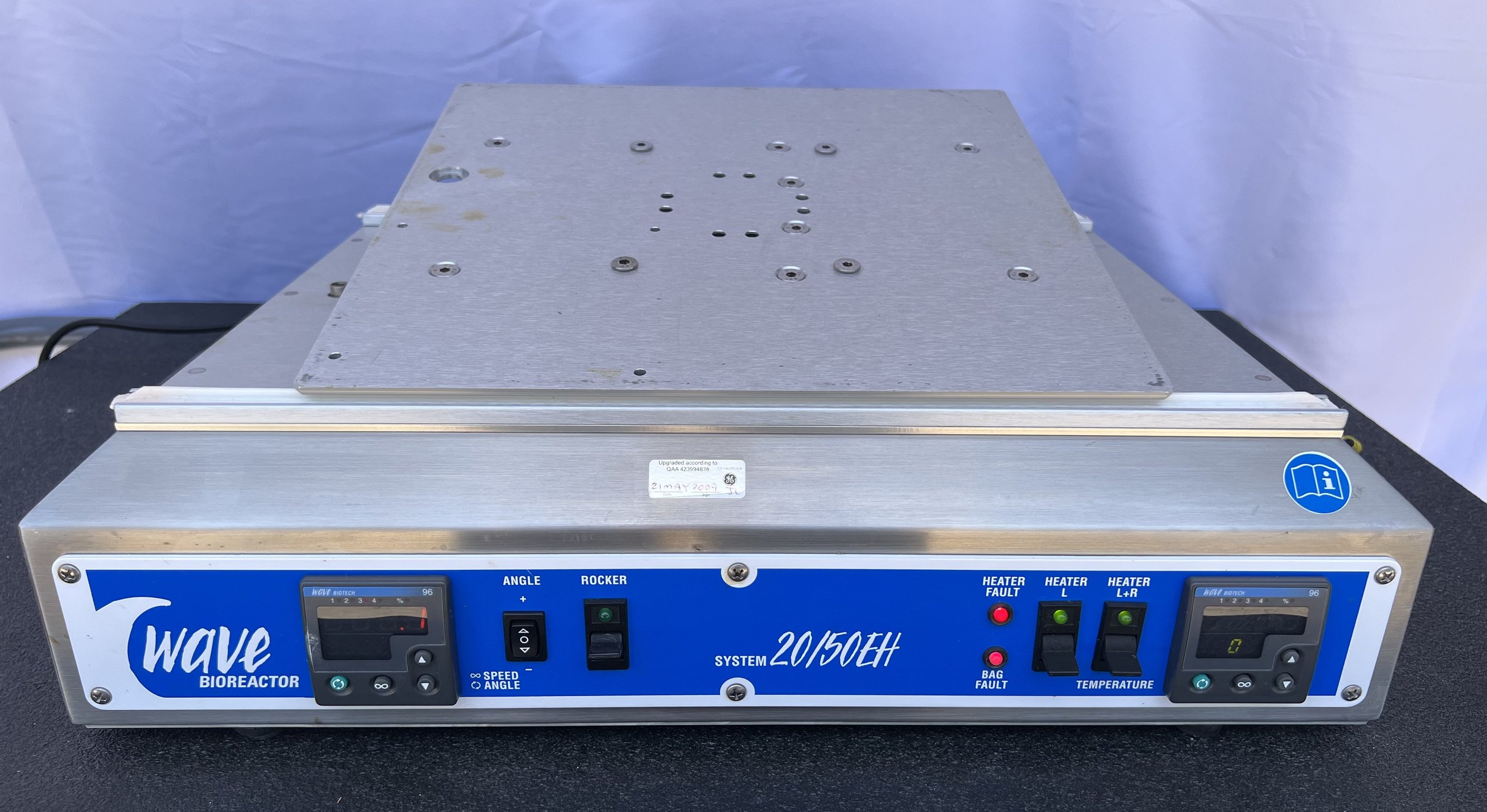

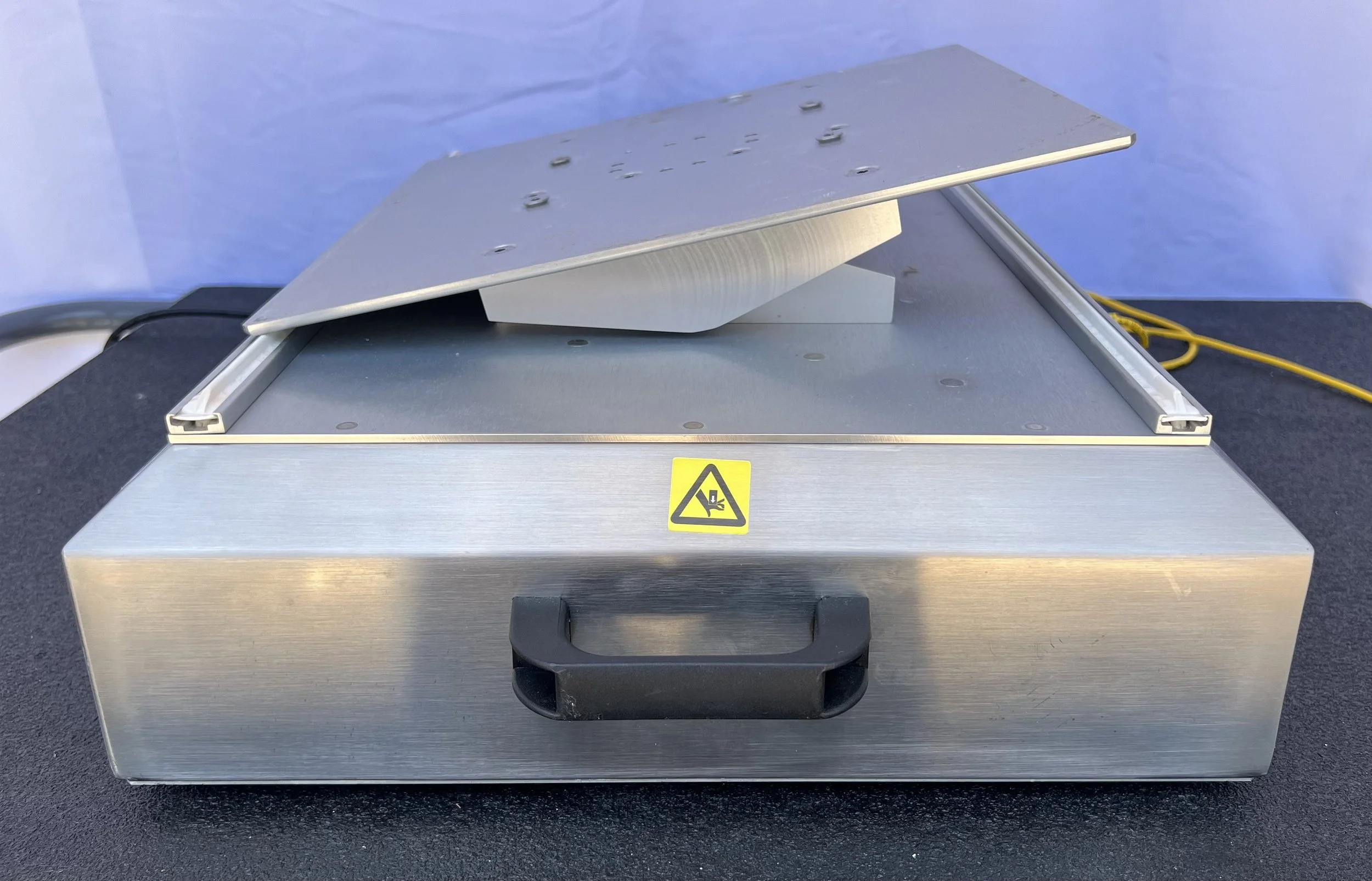

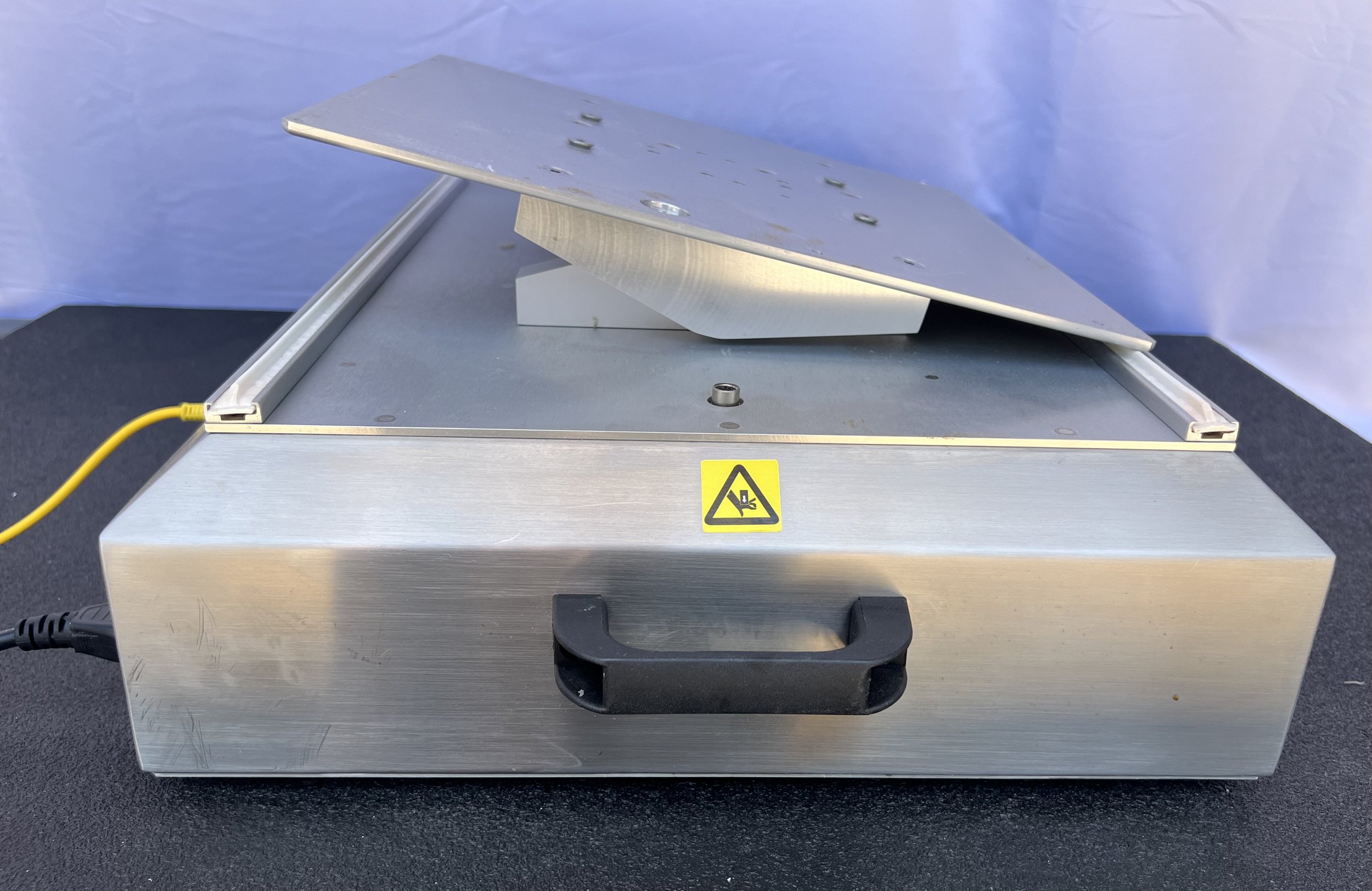

GE Wave Bioreactor 20/50 system - Base Rocker and Two Heat Plates

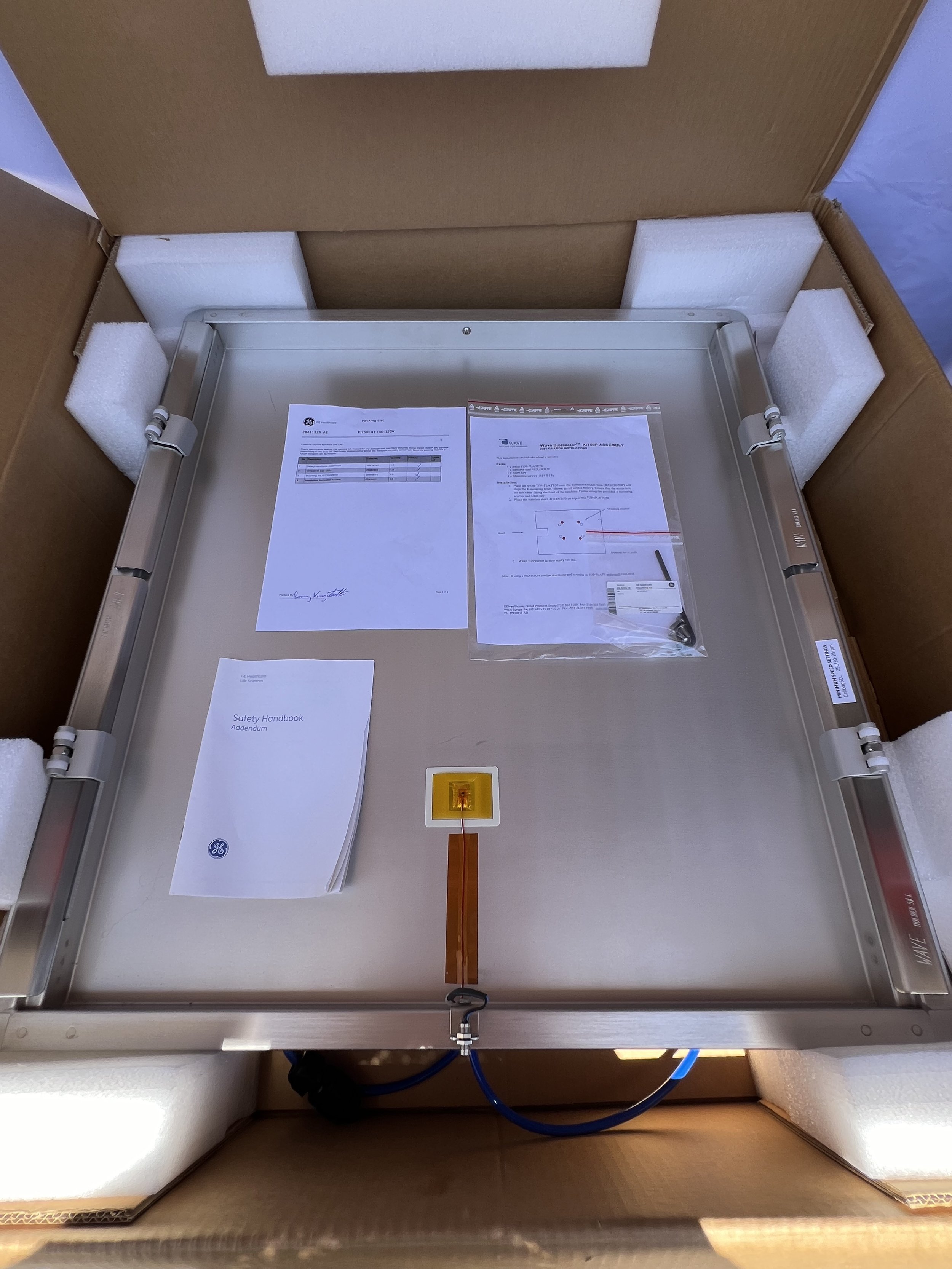

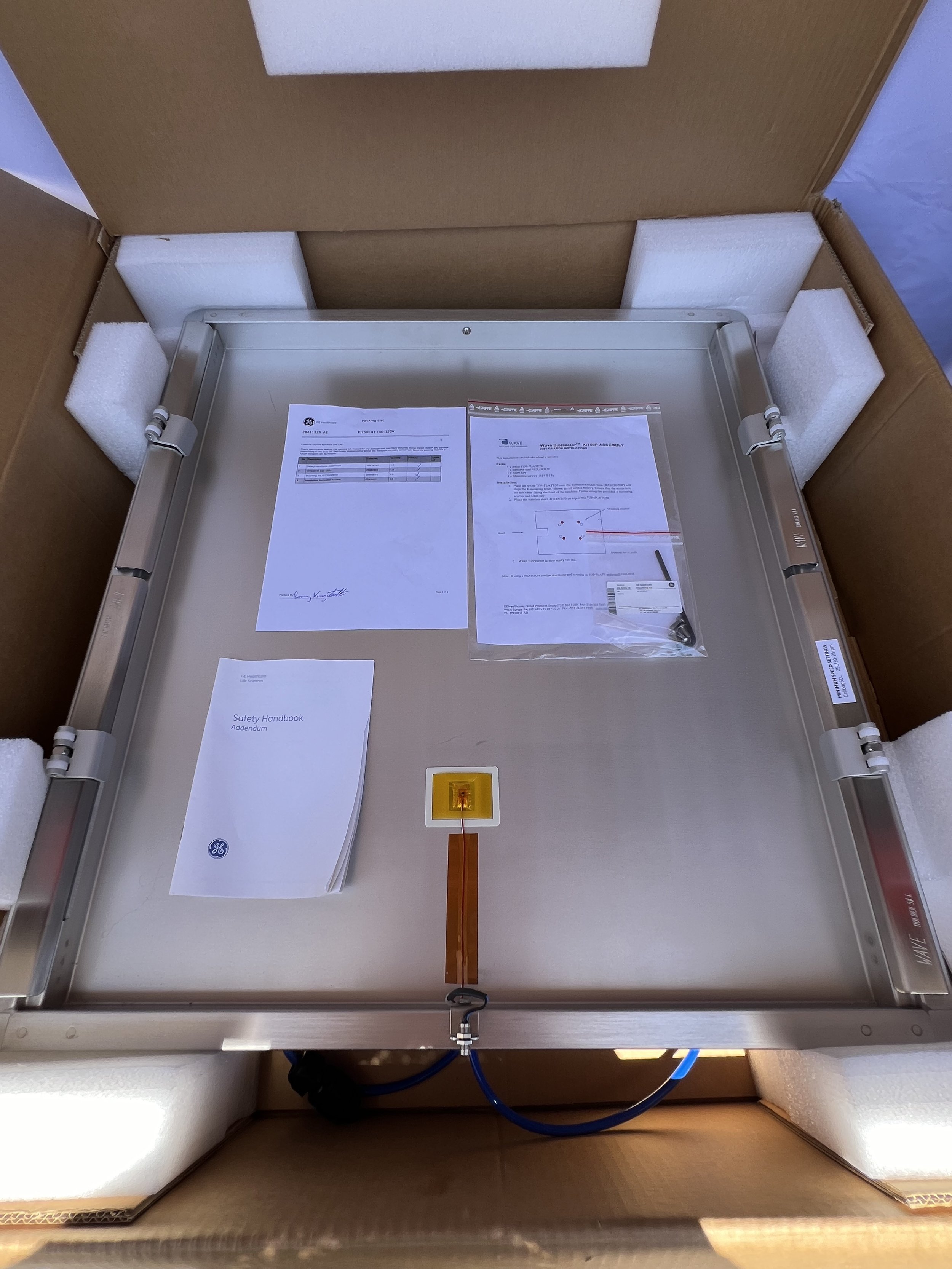

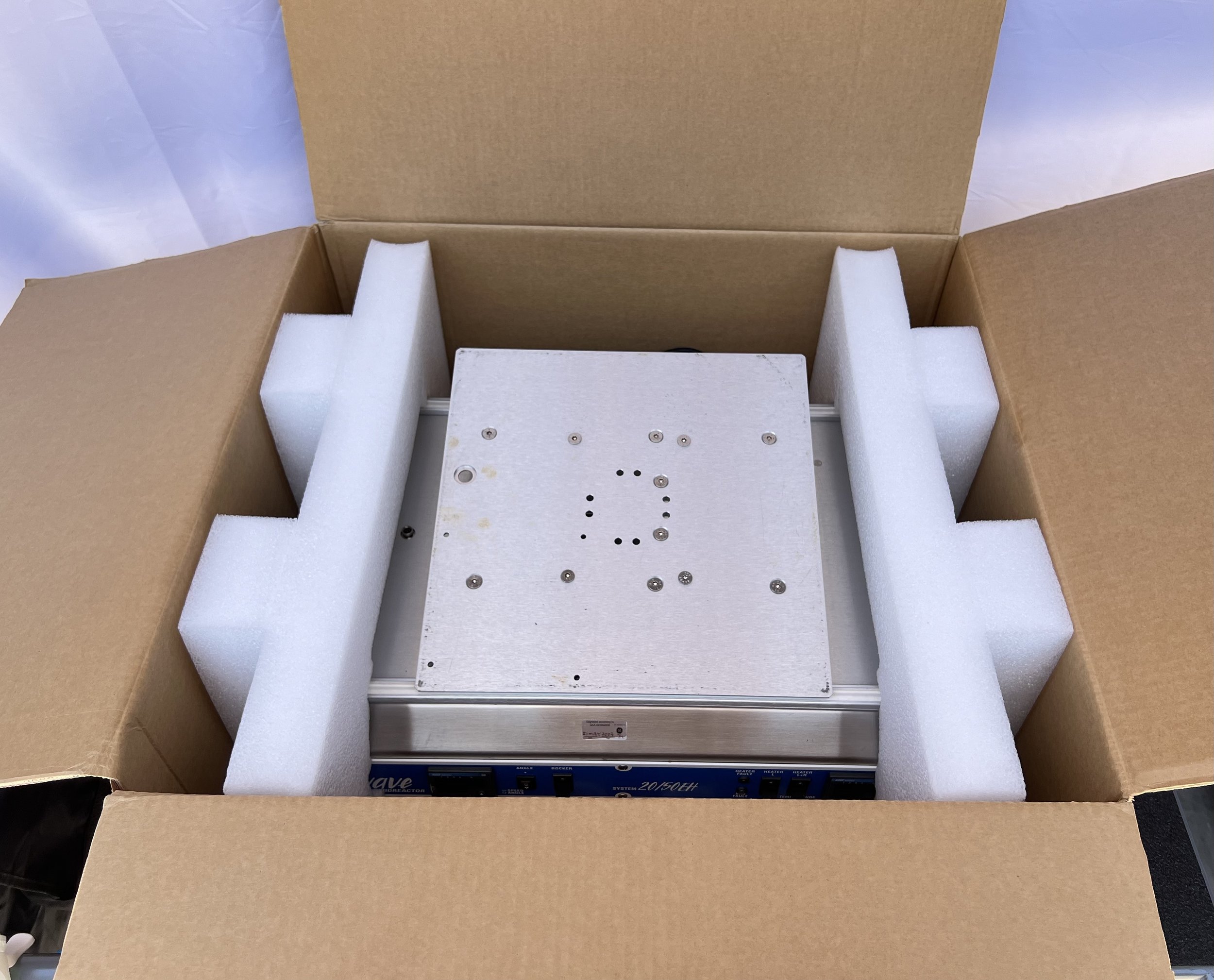

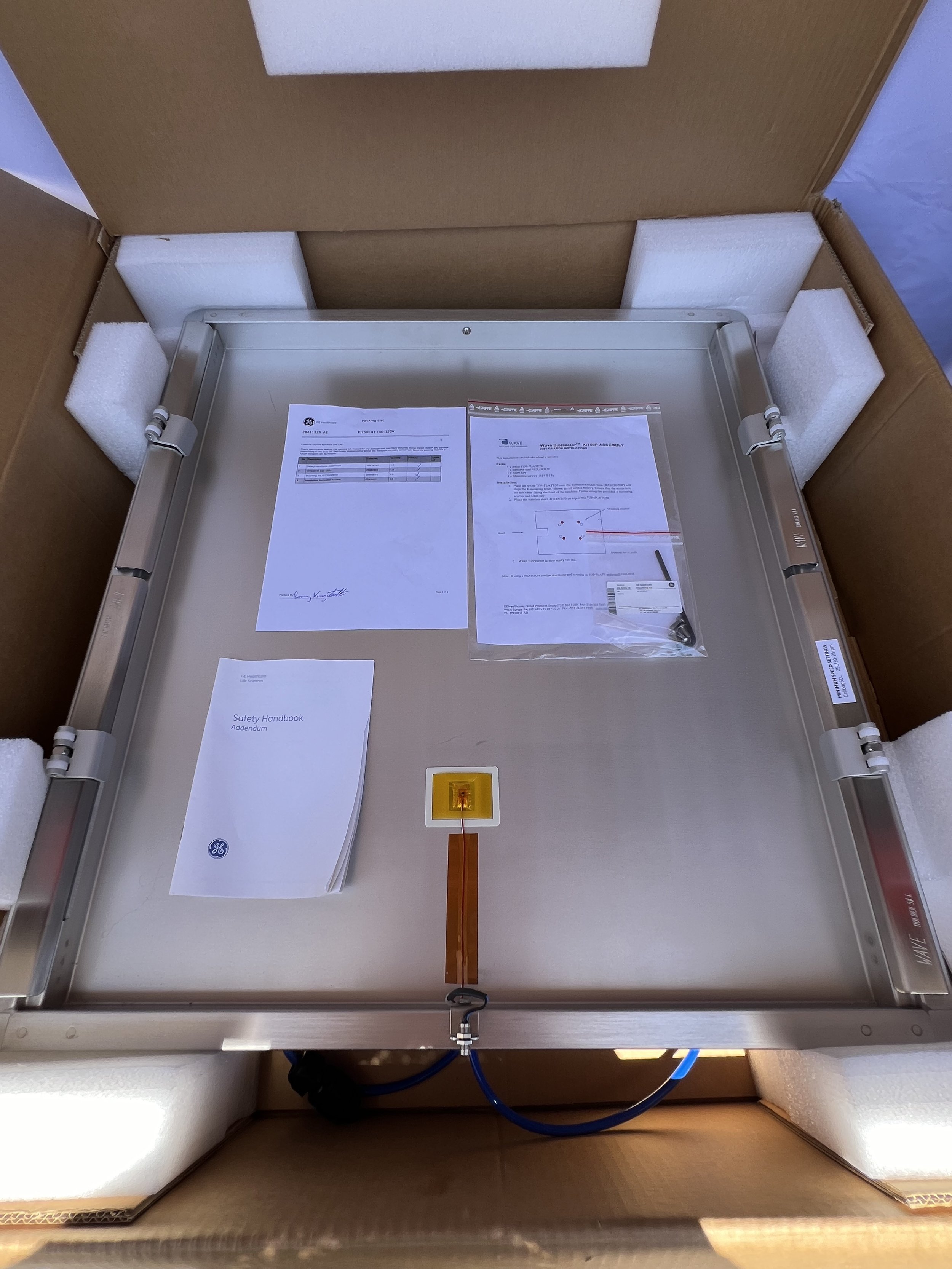

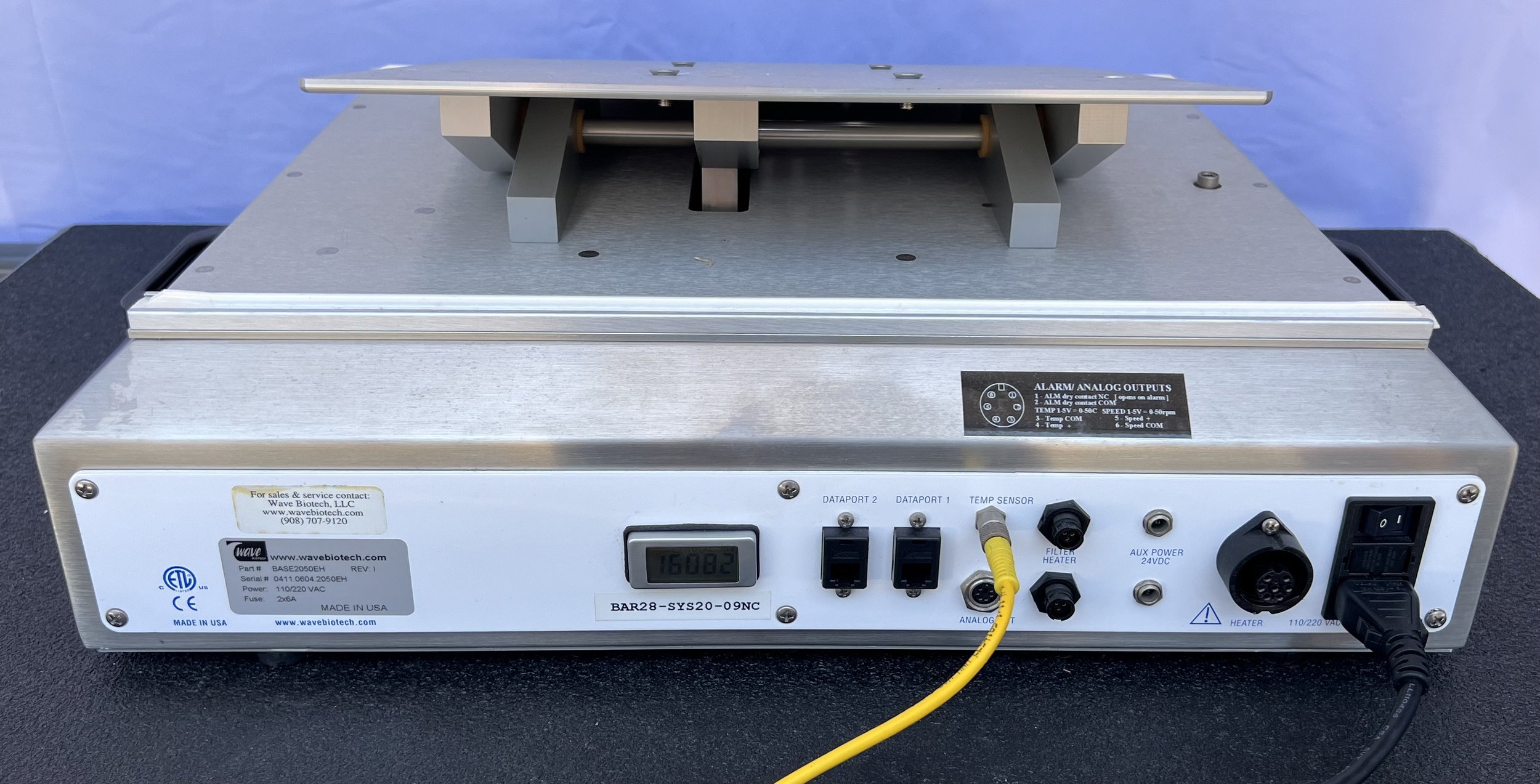

We procured this item from a large pharmaceutical company who was downsizing their operations in San Diego. This unit is in EXCELLENT condition, has been tested and functions as expected and even comes packed in original boxes and packaging. This includes the base unit and two heating trays.

The WAVE MixerTM is a system for mixing, dispersing, and reconstituting materials contained in plastic bags. Unlike any other mixer, it does not require an invasive device within the bag, thus guaranteeing a completely sterile operation. The sealed bag is placed on the WAVE Mixer platform. The platform rocks the bag back and forth at an optimized rate. The rocking motion rapidly (within 10 to 15 seconds) mixes the contents of the bag.

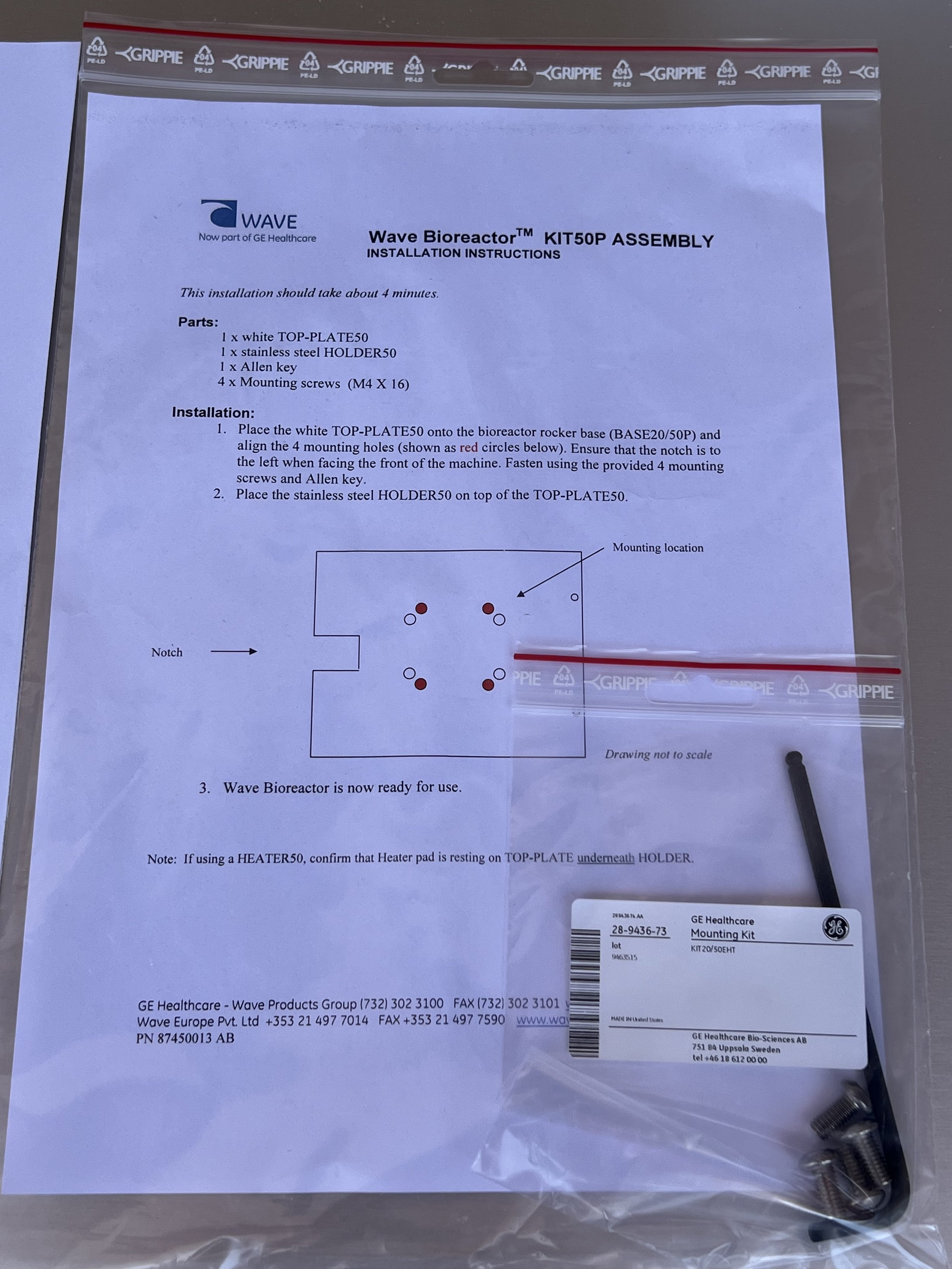

WAVE Mixer consists of two components: 1) the specially designed rocking unit, and 2) a stainless steel tray to hold the disposable plastic bag. The bag is partially filled (75% max for 20L, 70% max for 50L) with the liquid or powdered components to be mixed and then placed on the rocking unit. The rocking motion can be adjusted to provide the desired degree of mixing.

Standard bioprocessing bags or specialized M*BagTM from WAVE can be used. The M*Bag is optimized for the WAVE Mixer and has a large screw-cap port for easy addition of ingredients

Scalable

The Wave Mixer 20/50EHT can handle bags with a liquid volume up to 15 liters using the MIXKIT20EH and up to 35 liters using the MIXKIT50EH. The holders are interchangeable on the same Wave Mixer 20/50EHT base. Built-in temperature control and heating enables thawing and warming operations within a completely sterile environment.

Completely closed system

The WAVE Mixer is ideal for high containment applications and GMP operations. It operates as a completely closed system with no seals.

Utilizes standard bags

WAVE Mixer is designed to utilize standard bags from various manufacturers. This enables the use of previously validated containers for mixing applications.

No mechanical mixer

The rocking motion induces a wave action that promotes mixing without shear. Maintenance costs are reduced due to the absence of any mechanical seals or impeller.

Easy to operate

The WAVE Mixer has no complex piping. Simply place the bag with the materials to be mixed into the WAVE Mixer bag holder and start the unit. Mixing to homogeneity typically takes less than one minute.

Heating/thawing capability

Temperature control is achieved by the built-in heater unit. The heater is powerful enough to thaw frozen materials in a few hours.

We procured this item from a large pharmaceutical company who was downsizing their operations in San Diego. This unit is in EXCELLENT condition, has been tested and functions as expected and even comes packed in original boxes and packaging. This includes the base unit and two heating trays.

The WAVE MixerTM is a system for mixing, dispersing, and reconstituting materials contained in plastic bags. Unlike any other mixer, it does not require an invasive device within the bag, thus guaranteeing a completely sterile operation. The sealed bag is placed on the WAVE Mixer platform. The platform rocks the bag back and forth at an optimized rate. The rocking motion rapidly (within 10 to 15 seconds) mixes the contents of the bag.

WAVE Mixer consists of two components: 1) the specially designed rocking unit, and 2) a stainless steel tray to hold the disposable plastic bag. The bag is partially filled (75% max for 20L, 70% max for 50L) with the liquid or powdered components to be mixed and then placed on the rocking unit. The rocking motion can be adjusted to provide the desired degree of mixing.

Standard bioprocessing bags or specialized M*BagTM from WAVE can be used. The M*Bag is optimized for the WAVE Mixer and has a large screw-cap port for easy addition of ingredients

Scalable

The Wave Mixer 20/50EHT can handle bags with a liquid volume up to 15 liters using the MIXKIT20EH and up to 35 liters using the MIXKIT50EH. The holders are interchangeable on the same Wave Mixer 20/50EHT base. Built-in temperature control and heating enables thawing and warming operations within a completely sterile environment.

Completely closed system

The WAVE Mixer is ideal for high containment applications and GMP operations. It operates as a completely closed system with no seals.

Utilizes standard bags

WAVE Mixer is designed to utilize standard bags from various manufacturers. This enables the use of previously validated containers for mixing applications.

No mechanical mixer

The rocking motion induces a wave action that promotes mixing without shear. Maintenance costs are reduced due to the absence of any mechanical seals or impeller.

Easy to operate

The WAVE Mixer has no complex piping. Simply place the bag with the materials to be mixed into the WAVE Mixer bag holder and start the unit. Mixing to homogeneity typically takes less than one minute.

Heating/thawing capability

Temperature control is achieved by the built-in heater unit. The heater is powerful enough to thaw frozen materials in a few hours.

We procured this item from a large pharmaceutical company who was downsizing their operations in San Diego. This unit is in EXCELLENT condition, has been tested and functions as expected and even comes packed in original boxes and packaging. This includes the base unit and two heating trays.

The WAVE MixerTM is a system for mixing, dispersing, and reconstituting materials contained in plastic bags. Unlike any other mixer, it does not require an invasive device within the bag, thus guaranteeing a completely sterile operation. The sealed bag is placed on the WAVE Mixer platform. The platform rocks the bag back and forth at an optimized rate. The rocking motion rapidly (within 10 to 15 seconds) mixes the contents of the bag.

WAVE Mixer consists of two components: 1) the specially designed rocking unit, and 2) a stainless steel tray to hold the disposable plastic bag. The bag is partially filled (75% max for 20L, 70% max for 50L) with the liquid or powdered components to be mixed and then placed on the rocking unit. The rocking motion can be adjusted to provide the desired degree of mixing.

Standard bioprocessing bags or specialized M*BagTM from WAVE can be used. The M*Bag is optimized for the WAVE Mixer and has a large screw-cap port for easy addition of ingredients

Scalable

The Wave Mixer 20/50EHT can handle bags with a liquid volume up to 15 liters using the MIXKIT20EH and up to 35 liters using the MIXKIT50EH. The holders are interchangeable on the same Wave Mixer 20/50EHT base. Built-in temperature control and heating enables thawing and warming operations within a completely sterile environment.

Completely closed system

The WAVE Mixer is ideal for high containment applications and GMP operations. It operates as a completely closed system with no seals.

Utilizes standard bags

WAVE Mixer is designed to utilize standard bags from various manufacturers. This enables the use of previously validated containers for mixing applications.

No mechanical mixer

The rocking motion induces a wave action that promotes mixing without shear. Maintenance costs are reduced due to the absence of any mechanical seals or impeller.

Easy to operate

The WAVE Mixer has no complex piping. Simply place the bag with the materials to be mixed into the WAVE Mixer bag holder and start the unit. Mixing to homogeneity typically takes less than one minute.

Heating/thawing capability

Temperature control is achieved by the built-in heater unit. The heater is powerful enough to thaw frozen materials in a few hours.

User Manual here:

https://acmerevival.com/wp-content/uploads/2021/05/GE-Wave-Biotech-CO2MIX20-CO2-Mix-Digital-ControllerUserManual.pdf